Products > Control Valves

A Control Valve is a device capable of modulating

flow at varying degrees between minimal flow and full capacity in

response to a signal from an external control device. In a process

control loop, an Electronic Controller and Sensor is used in conjunction with a Control Valve to

maintain a process variable at a desired set point. The controller

compares the sensor signal to the set point and outputs the appropriate

response signal to the control valve. The control valve will then

modulate to provide the flow response required to maintain the process

variable at the set point. In the case of a pneumatic control valve

such as the W910 Series, a current-to-pressure (I/P)

transducer is required to convert the electrical signal from the

controller to the air pressure signal needed to operate the pneumatic

valve. Watson McDaniel is unique in its ability to provide all the

necessary components to create a complete control loop.

The Watson McDaniel W910 Series Pneumatic Control

Valve offers high quality at an economical price and

incorporates many features found only on more expensive units. A variety

of models are available to provide the flow response required by the

application.

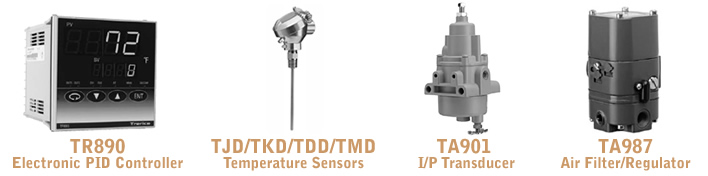

In addition to the control valve, Watson McDaniel also

offers the following control loop components: The TR890 Series

Electronic PID Controller, the TA901 Electropneumatic

(I/P) Transducer, the TJD/TKD Thermocouple Temperature

Sensors and the TDD/TMD RTD Temperature Sensors.

The TA987 Air Filter/Regulator is available for

filtering and regulating plant compressed air for providing clean, dry

air at the proper pressure to the W910 Series Pneumatic Control Valve. A

variety of Thermowells are available to protect and

isolate the temperature sensor stems from the process fluid.

Products > Control Valves