Products > Condensate Return Pumps

The Watson McDaniel PMP Series of Pressure

Motive Pumps are designed to transfer hot

condensate (or other liquids) without the use of electrical

power. The mechanical seals in standard electric condensate return

pumps begin to have difficulty when handling condensate in excess of 195°

F. Seal failure is virtually guaranteed when condensate temperatures

reach 203° F due to flashing of the condensate across the seal face. It

is therefore required to cool condensate in order to prevent seal failure

prior to pumping using electric pumps. PMPs do not have seals and

therefore will handle condensate well in excess of these

temperatures.

The primary application for the PMP is pumping condensate from a

process application or condensate collection area back to the condensate

return system. All PMP Series stand alone units are furnished with

pump tank, check valves, and internal pumping mechanism. The PMPSP Sump Drainer is a special PMP designed for pumping

water out of low lying areas or pits. It is an excellent solution where

there is no access to electricity.

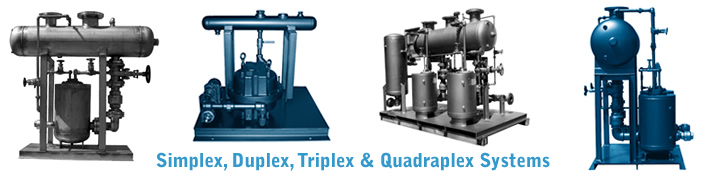

Watson McDaniel also offers Pumps with Receiver

Tanks which consist of one or more stand alone pump units

connected to an appropriately sized receiver tank mounted on a common

base. Additional pumping units can be used for increased capacity or pump

redundancy in case of failure. Simplex, Duplex, Triplex and Quadraplex condensate pumping systems are available.

A Pump-Trap Combination (PMP with Steam Trap) is used

when draining condensate from a single piece of heat transfer equipment

whose steam flow is being controlled with a modulating type valve.

When a modulating valve controls the flow of steam to a heat exchanger, a

stall condition can develop. Stall occurs when the modulating valve

closes and steam pressure downstream of the valve is unable to push the

condensate into the return line and it backs up into the heat

exchanger. A pump-trap combination will eliminate this

problem. Watson McDaniel Pump-Traps are available

with either an internal steam trap (Model PMPT) or an external

steam trap (WPT Series).

Watson McDaniel’s fully-qualified fabrication facility is ASME

Code Certified. Our engineers can design and build complete custom condensate pumping systems to meet all your

requirements.

Non-Electric Pressure Motive Pump (PMP) Categories:

Stand-Alone PMP Units: Watson McDaniel PMP Series

Pressure Motive Pumps come complete with pump tank, check valves and

internal pumping mechanism. The following models are used for condensate

return applications:

PMPC - The Model PMPC pressure motive pump body &

cover are manufactured from Ductile Iron. ASME “UM” code stamp is available.

PMPF - The Model PMPF pressure motive pump is designed

for high pressure applications. Pump body and cover are

manufactured fromCarbon Steel and receive the ASME “UM” code stamp.

PMPSS - The Model PMPSS pressure motive pump body

& cover are manufactured from 304L Stainless Steel.

These tanks are designed to be used in harsh corrosive environments and

receive the ASME “UM” code stamp.

PMPBP - The Model PMPBP is an extremely

high-capacity pressure motive pump for applications requiring

large transfer of condensate or other liquids. Pump body and cover are

manufactured from Carbon Steel. The internal operating

mechanism functions identically to other pumps in the PMP series. ASME “U” code stamp is available.

PMPM - The Model PMPM pressure motive pump has an extremely low profile. These low-profile tanks

are required when draining condensate from process equipment positioned

close to the ground which limits the filling head of the pump. Pump body

and cover are manufactured from Cast Iron.

PMPLS- The Model PMPLS pressure motive pumps are low profile. These tanks are often required when

draining condensate from process equipment positioned close to the ground

which limits the filling head of the pump. Pump body & cover are

manufactured from Carbon Steel and receive the ASME “UM” code stamp.

The PMPSP Sump Drainer (also known as

“The Pit Boss”) is a special PMP designed for pumping

water out of low-lying areas or pits. Sump drainers are similar to

the standard PMP models except that they discharge the condensate

vertically upwards. This piping configuration allows them to easily fit

into below ground sump pits with limited space.

Watson McDaniel manufactures PMPs with Receiver Tanks.

The pumps are available in Ductile Iron, Cast Iron or Fabricated Steel.

The receiver tanks are manufactured from Carbon Steel. These units come

fully-assembled with one or more stand-alone PMP units and an

appropriately sized receiver tank, mounted on a frame and skid base.

Assemblies are available in Simplex (one pump), Duplex (two pumps), Triplex (three

pumps) and Quadraplex (four pumps).

Watson McDaniel Pump-Traps are available with either

an internal steam trap or an external steam

trap to suit individual application requirements:

The Model PMPT low-profile pressure motive pump has an internal steam trap for applications requiring compact

design due to spatial constraints. It is an excellent choice for drainage

of various modulating process equipment.

The WPT Series are stand-alone pump units with an

appropriately sized external steam trap preassembled at

the factory and mounted on a common base plate, allowing for easy

installation. Pump-Trap combos with an external trap are suitable when

capacity requirements exceed internal steam trap designs. These units are

available in several sizes and capacities.

Watson McDaniel’s fully-equipped ASME Code

Certified manufacturing facility stands ready to

assist you with all of your fabrication needs. Our engineering staff

specializes in the design of Pressure Motive Condensate Pumping

Systems for both industrial and institutional applications. You

can order either standard packages, available from stock, or specialized

systems to meet your specific needs. Contact factory for further

information.

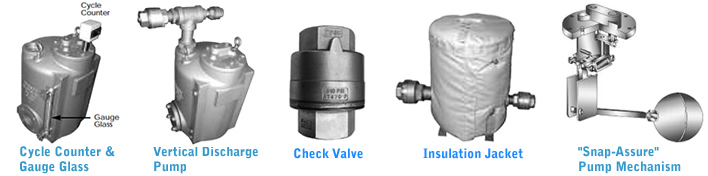

Watson McDaniel Pressure Motive Pumps are available with

several accessories and options. In addition to the items shown above,

Watson McDaniel also offers the following accessories and options: ASME Code Stamps, Pre-Piped Pressure Regulating Valves,

Drip Leg Stations and Exhaust Lines, and Rebuilt Mechanisms.

Electric-Powered Pumps:

Watson McDaniel Models W4100 & W4200 Electric Condensate

Pumps are used for condensate return applications at temperatures

up to 190°F. The pump tanks are available in either Carbon Steel (W4100)

or Cast Iron (W4200). Standard features include Bronze-fitted centrifugal

pumps, energy-efficient 3450 RPM motors and heavy-duty float switch.

Available options include simplex or duplex packages, oversized or

Stainless Steel receivers, gauge glass, thermometer, discharge pressure

gauge, isolation valves, magnetic starter, mechanical or electrical

alternators, 1750 RPM motor, NEMA control panel and high temperature

(250°F) components.

Products > Condensate Return Pumps